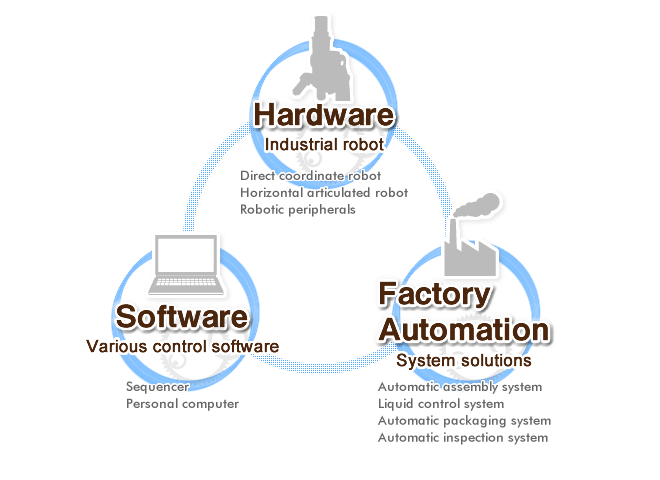

Skill Engineering Corp. can meet the needs of the FA with various individuality.

In addition, We meet automation technology, increase in speed, intelligence, miniaturization and high functionality.

We have a motion system and own mechanical mechanism.

Because, it is in order to meet flexibility of the system, scalability, and economy.

And we have realized various equipment configurations based on the total technology network that links the equipment and systems.

We have full support for all automation needs. They are including the automatic assembly system of trust backed by technical capabilities of excellence, from the automation of manual area, of assembling a total system of each plant in a variety of technical capabilities crimping machine, robot, parts feeder, such as a conveyor line is to ensure.

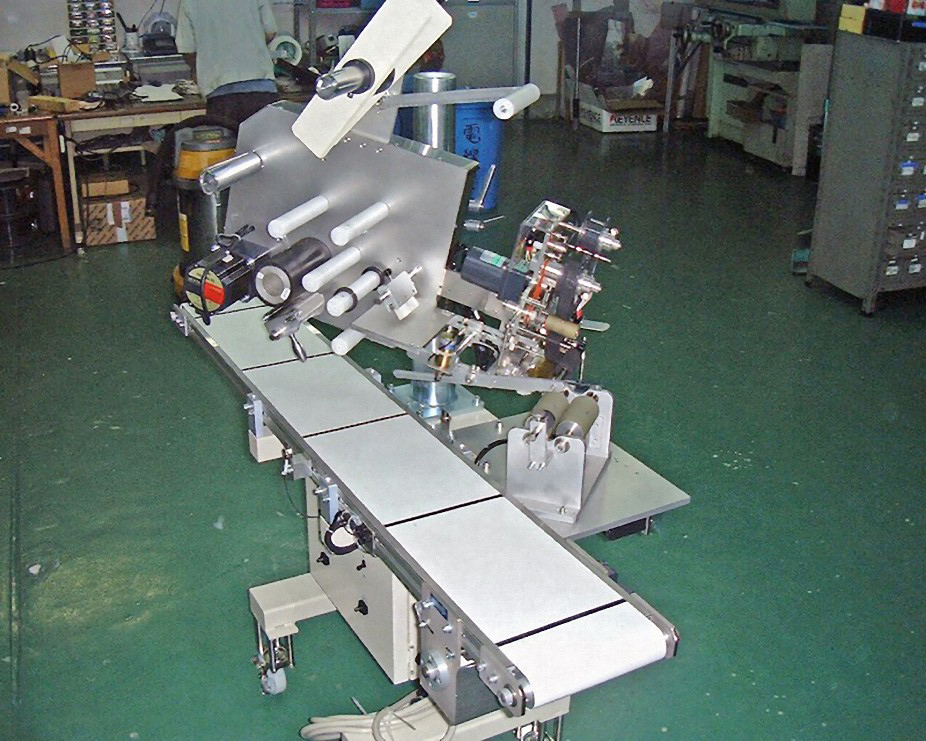

| Automatic wrapping system | Meter, printer, labeler, and sealing machine, etc. |

|---|---|

| The main technology<Calculation, wrapping, and recording equipment> We calculated a same shape product or a heteromorphic compound product by sensor cameras etc. And, we have abundant achievement that make the machine that wraps it by full automation, the machine that turns it on to the palette, and the device that makes them line up. |

|

| Automatic inspection system | Various measurement equipment, electrical test equipment, shape verification device, visual inspection equipment, etc. |

| The main technology<Measurement, measurement, and inspection> System to inspect the load cell in a non-contact, laser, micrometer, due to camera, only supply the good products to eliminate automatically defective also has a number of achievements. |

|

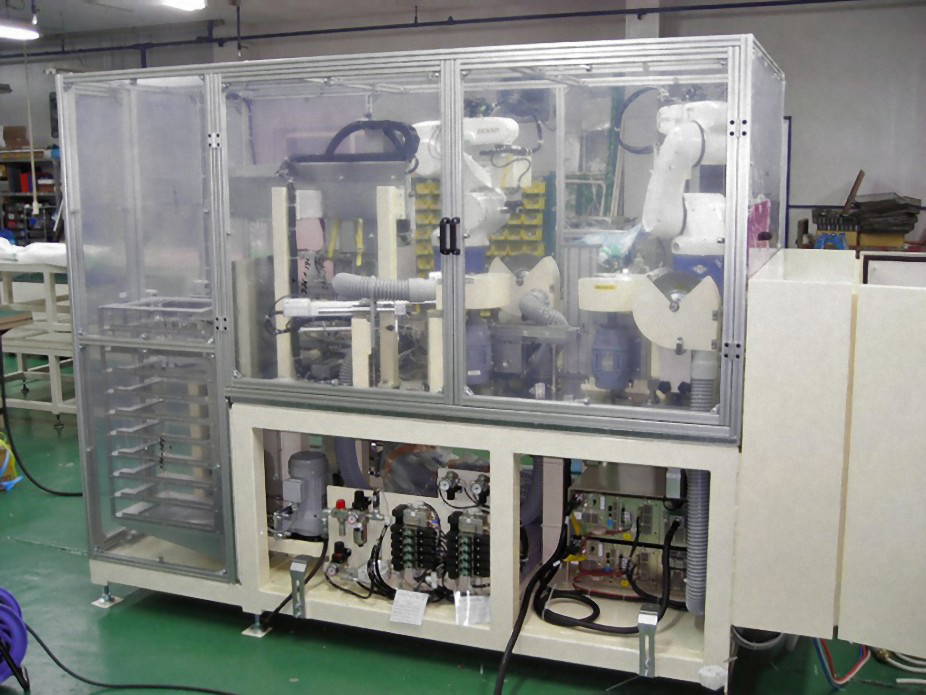

| Industrial robot | Direct coordinate robot, the horizontal articulated robot, various robotic peripherals, etc. |

| The main technology<Horizontal transport and vertical> We meet to fine the transport of fully automatic high and low, horizontal and feeding, etc. under the counting manage the work and parts. |

|

| Liquid control system | Potting, loading, welding, casting, etc. |

| The main technology<Supply labeling> <Record system> Even in special products and parts that you thought that everyone make up to now is impossible, alignment has enabled a whole new idea for us. We can paste the label to print out in all automatic counting varieties, and work.. |

|

| Automatic assembly system | Screw tightening machine, rivet crimping machine, pin setter, soldering machine, feeder, Palletizer, etc. |

| The main technology<Attaching and tightening machine> we align the parts of various sizes, and pumped, temporary tightening, and the final tightening by torque management . In addition, we are working to fusion of the work by the rhythm of the production line of the main automation rivet, such as caulking. |